Can AI help America make stuff again?

A British startup, CloudNC, is reshaping American manufacturing one precision part at a time.

There’s absolutely no room for error with the precision parts that MSP Manufacturing in Bloomington, Ind., makes for the aviation industry—including cases and clamps that hold a plane’s instruments securely in the cockpit, cooling vents for avionics, and switch guards to prevent pilots accidentally shutting down engines or, in fighter jets, launching missiles.

To produce those crucial parts with sub-millimeter precision, MSP has long used CNC (computer numerical control) machines. These machines use mills, lathes, and drills to cut, shape, and bore metal to the exact specifications set by a human operator.

But those highly trained operators are in short supply in the United States, with an aging industrial workforce and few younger workers with the necessary skills. And this is maddeningly time-consuming work: Programming one part into a CNC machine can take from an hour and a half to an entire day, says Johnny Goode, MSP’s president and chief operating officer. “We had about three [programmers],” Goode says. “And it was kind of a bottleneck.”

Then last year, Goode was at an aviation trade show in England when he saw something remarkable: a new kind of AI-powered software that could program a CNC machine to make one of those hour-and-a-half parts in just seven minutes. MSP’s human CNC operator then spent another 15 minutes refining the part manually. But the time savings was significant.

“I was like, holy snap, this is going to be a game changer,” Goode tells Fortune, adding that the return on investment seemed obvious. “Going from 90 minutes to 22 minutes is a big deal, and we’ve seen that get even better as we’ve learned to use the software more.”

The company behind that software is CloudNC, a London-based startup that’s part of a quiet revolution transforming American manufacturing. By using artificial intelligence to automate one of the most skilled and time-consuming aspects of factory work—programming the robots that cut metal parts—CloudNC is helping manufacturers overcome two critical challenges: a severe shortage of trained workers, and the pressure to produce parts faster and cheaper than ever before.

The skills crisis

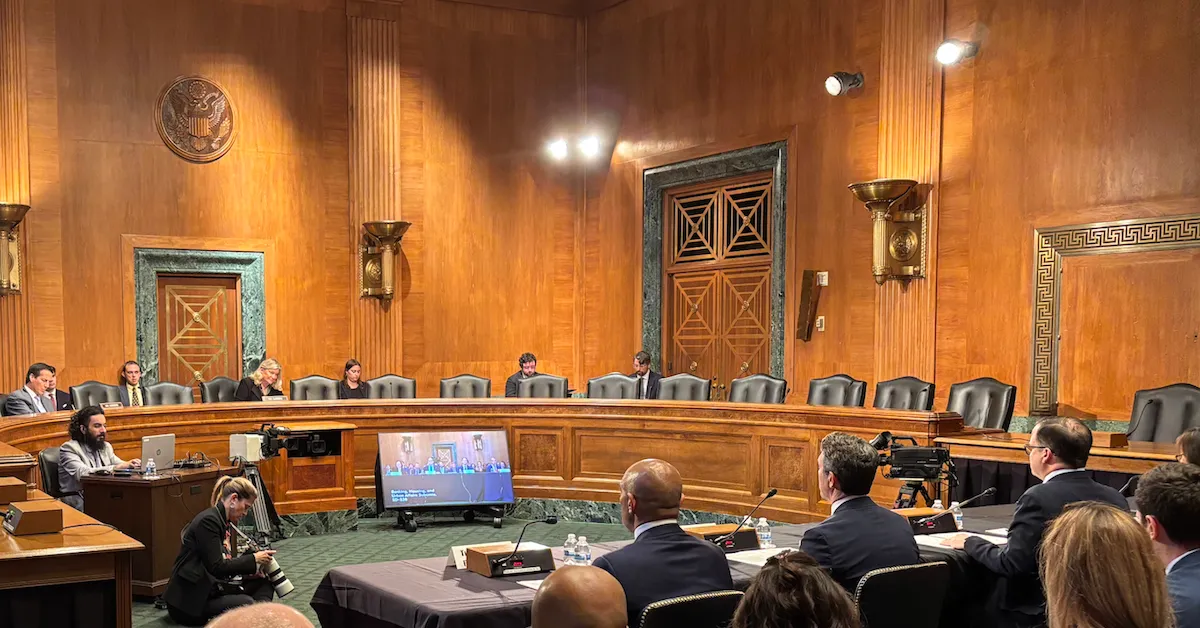

The Trump Administration says it wants America to make stuff again—and its tariff policy is designed, in part, to push companies to “reshore” manufacturing jobs that they had moved to Asia and other low-wage countries over the past three decades.

But U.S. manufacturing is facing a severe labor shortage. A 2024 analysis of the U.S. industrial workforce by Deloitte and the Manufacturing Institute estimates that 1.9 million manufacturing jobs could go unfilled by 2033 due to skills shortages. And CNC operations is one of the areas with the largest skills deficit.

The roots of this crisis run deep. Nearly 70% of the machinist workforce is over the age of 45. And surveys have consistently shown that young people are uninterested in entering the manufacturing sector. A 2023 survey from the research firm Soter Analytics found that only 14% of Gen Z (people aged 13 to 28 currently) would consider a manufacturing job, with many in the cohort perceiving the sector to be unsafe and incompatible with the flexible working arrangements they value.

Even for those willing to enter the field, training a new CNC programmer takes years. And the work requires extraordinary precision—mistakes can cost tens of thousands of dollars and damage expensive machinery.

“When I went into this business 10 years ago, people talked about a skills gap. Now they call it a skills crisis,” says Theo Saville, CloudNC’s cofounder and CEO. “There have been fewer machinists in industry every year for the last 35 years, give or take. The numbers keep going down, while the industrial production requirements keep going up.” Globally, the need for CNC machined parts is expected to grow about 10% annually over the next seven years, according to forecasts from the research firm Fortune Business Insights (which has no connection to Fortune), with the demand for high-precision parts in aerospace, telecom, and medical devices driving this trend. But many manufacturers don’t have enough CNC operators to keep up with the accelerating demand.

A submarine contest

Saville, CloudNC’s cofounder and CEO, hit upon the idea for the company as a mechanical engineering student at the University of Warwick in England. Saville and his fellow students had entered an annual competition that asks students to design and build a human-powered submarine and then pits these subs against one another in races held at the torpedo range of the U.S. Naval Surface Warfare Center in Carderock, Maryland. Saville’s team had 30 weeks to put their sub together, but hit a snag manufacturing the metal components they needed. To get the parts made, he says, “the lead time was 10 weeks.” The figure struck Saville as insane, he recalls, because he had seen 3D printers produce complex plastic parts overnight.

Meanwhile, Warwick’s engineering workshop had a CNC machine sitting idle. “I said, ‘It’s in front of me. Let me just use it.’ But, they said, ‘No, you need five years of training,’” he says. That, too, struck Saville as insane.

With a minor in computer science and AI, Saville thought there had to be a better way to go from component design to CNC machine program than relying on a human manually coding all the steps. “We started with the belief that we should be able to press a button and get metal parts,” Saville says. “We didn’t realize how hard it was going to be.”

He didn’t convert the workship’s machine in time for the submarine contest: It took Saville and his cofounder Chris Emery, who is now CloudNC’s chief scientist, eight years to develop AI software that could master the complex operation of CNC machines. “I’ve got a machine that has hundreds of cutting tools. I can use one of those tools, or all 200 of them, and I can move them at any speed, in any direction, any angle, any advancement per revolution,” Saville says. “And then I’ve got [metal] chip buildup, I’ve got vibration, I’ve got heat. I’ve got different materials to consider. I’ve got the torque and the power of the machine and the limits of its axis speed. Basically there are like 30 subproblems inside that overall problem of “How do I make this part?”

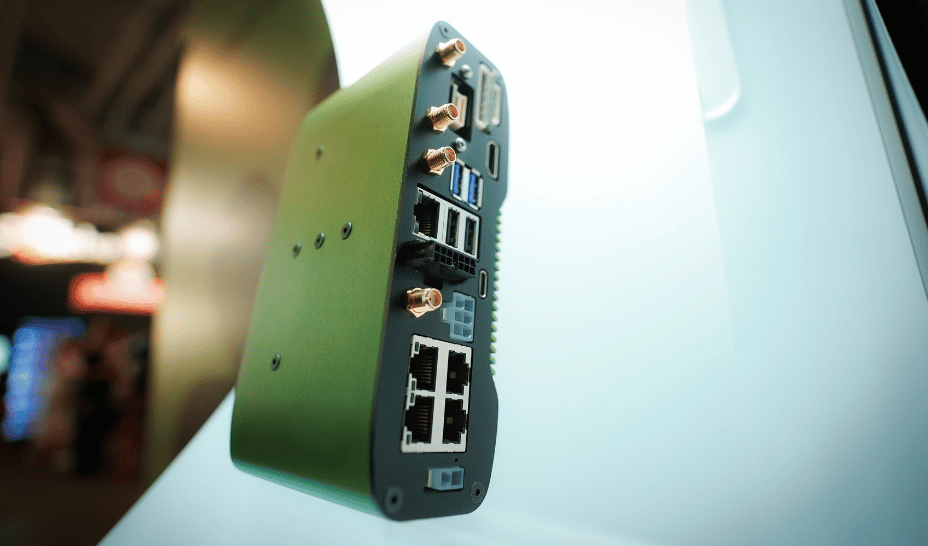

The solution CloudNC hit upon uses a combination of small AI models, each trained to solve just one of those subproblems, working in tandem with more standard software programs. It takes as its input a digital three-dimensional engineering drawing of a part, created using computer-aided manufacturing (CAM) software from any of several different vendors, including Autodesk, Siemens, or Sandvik.

Here’s how it works on the factory floor: CloudNC’s “Cam Assist” AI software analyzes the part to be made, quickly running through hundreds to thousands of different ways a CNC machine could produce it, using a range of tools. “Then it’s going to start running optimizations,” Saville says, discarding inefficient approaches and looking for the ones that work best. Once it has hit upon a good approach, it develops the specific instruction set for the CNC machine to execute that strategy. A machine operator can then use a USB stick, or in some cases a network connection, to feed those instructions to the CNC machine.

Solving the data dilemma

Obtaining data to perfect these AI models is extremely difficult, Saville says. When it comes to the right approach for a brand-new part, the know-how exists only in the minds of the human CNC operators themselves. And while many manufacturers do save the programs for parts they have successfully made before, the fragmented nature of the manufacturing industry means that large datasets on how to make a diverse set of parts simply don’t exist.

“Every factory’s data is completely its own,” Saville says. “The machine tool manufacturers don’t have it. The software providers don’t have it. Everyone is resolving the same problem every day in different buildings and not sharing.”

And the data about how to make parts correctly is only part of what a company like CloudNC needs to build AI software for CNC machines. It is also helpful to know the mistakes, Saville says. What strategies didn’t work? Almost no manufacturers keep records of these mistaken approaches.

That’s why a lot of the secret sauce CloudNC used to build its AI models was brewed in a small manufacturing operation that CloudNC itself runs in Essex, to the East of London. Here, in a 15-person factory, the AI company operates a number of CNC machines making real components for paying customers. The data CloudNC captures in the process helps it improve its software.

Competing on time instead of price

While CloudNC has largely had the market for AI-powered CNC software to itself so far, competition is starting to emerge. Plyable, another U.K.-based entrant, is trying to build AI to automate some of the work CNC machines do—particularly creating molds and composite parts. Manukai, based in Zurich, Switzerland, is another AI startup targeting the CNC market. Meanwhile Formlogic, a company that had helped make parts for SpaceX, closed its Pittsburgh headquarters and laid off most of its staff last year after failing to win enough business.

MSP’s Goode says his company’s CNC operators have readily taken to using CloudNC, and that it has even encouraged other employees to improve their CNC programming skills so that they can use the AI software. MSP has a rule that an operator needs to have experience producing a part on their own before they are allowed to use CloudNC’s software. “We’re getting better programmers now too,” he says. “So that was an unforeseen byproduct of CloudNC.”

Goode says that CloudNC has enabled MSP to use its CNC machines much more efficiently than in the past—and deploy its human CNC programmers more productively too. “Instead of having, you know, 10 programmers, or people just always programming, I can have a few, and they’re able to do more,” he says.

It has also enabled MSP to compete for orders that require rapid turnarounds, which the company would not have been able to fulfill before. “If they said less than three weeks, we wouldn’t have even quoted it before,” Goode says of rush orders. With the new AI system, he says, “We’ve taken on a couple mission critical parts for some Fortune 500 companies, as well as the [Department of Defense] directly, and got it in and out of here in less than two or three weeks—which, prior to CloudNC, was unheard of.”

What’s more, because MSP can charge a premium for delivering rush orders, the software has enabled MSP to increase its profit margins.

Scaling the solution

Saville declined to provide current sales and profit figures for CloudNC, but says CloudNC’s business has exploded over the past year, growing from “actively zero revenue just over a year ago” to “multiple millions” with hundreds of customers, mostly small to medium-sized machine shops across the United States. Financial filings with UK business registry Companies House show that the company had sales of about $3 million in 2024, but lost about $22 million.

CloudNC has received about $78 million in venture capital funding to date. This includes a $45 million funding round in 2022 that was led by Autodesk, with participation from Lockheed Martin and the fund British Patient Capital. Earlier investors, which included the London-based venture capital firm Atomico, as well as Episode 1 Venture and QVentures also participated in that financing. Ultimately, Saville says, his goal is “one-click manufacturing” where a customer could go directly from design idea to finished product in minutes or hours, instead of days or weeks.

That’s the kind of solution that might help American manufacturers close the looming skills gap and ensure that more things get “Made in America” again.

This story was originally featured on Fortune.com

![What Is a Markup Language? [+ 7 Examples]](https://static.semrush.com/blog/uploads/media/82/c8/82c85ebca40c95d539cf4b766c9b98f8/markup-language-sm.png)