AI is changing how employees train—and starting to reduce how much training they need

As workers focus on acquiring AI skills, AI is emerging as a useful tool to hone other important job skills.

Proficiency with AI tools has quickly become a top skill, and companies are working to train their employees how to use it. At the same time, AI is also emerging as a useful training tool in its own right.

Across industries, AI is helping companies create training materials faster and more efficiently, as well as allowing them to design new, more interactive methods to train workers. Artificial intelligence technology is also enabling a shift toward on-the-job instruction that can guide employees in real time. The benefits can be wide-ranging, from massive cost savings for the companies to providing a safer place to simulate tasks in which the cost of an error could be severe.

Creating training content just got easier

BSH Home Appliances, a subset of the multinational technology Bosch Group, has been using an AI-generated video platform called Synthesia to create material ranging from compliance trainings to technical trainings. The platform allows users to quickly generate videos from prompts or documents and include generic avatars in their videos or even AI avatars of themselves. The videos can range from two minutes to 45 minutes, and the company has been significantly scaling its use of the platform after seeing a 70% cost savings in external video production.

Previously, the company’s learning and development teams had to purchase training video content from a vendor or repeatedly host and record training sessions. Lindsey Bradley, learning and development partner at BSH, says the platform has reduced instruction hours for facilitators and made it possible for a wide variety of stakeholders across the company to create training videos and seamlessly update them as often as needed. The other major benefit has been the ability to instantly translate and localize training content, which is typically a costly yet necessary task for a multinational company with employees in several countries.

“One of our training sessions that covers energy, environment, and health compliance was created with the platform. In the learning hub for employees, the training session is offered in more than 10 languages, and all the trainer has to do is switch the language in the system,” says Bradley. “The content and script can remain the same. No language experts were required, no actors, etc., because the platform offers a wide range of languages already available that our learning and development teams can choose from for our videos.”

While customers are increasingly using the platform to create videos for all different purposes, employee training and learning and development has been the most common use case so far, says Synthesia cofounder and CEO Victor Riparbelli. The company is continuing to take advantage of the advancements in AI to make videos even more engaging, moving beyond broadcast to interactive choose-your-own-adventure-style videos that provide training paths customized to individual needs.

“An interactive AI video in Synthesia might start off the same for everyone, but it might branch into a more detailed explanation for more advanced viewers, for example,” Riparbelli says.

Welcome to the simulation

Sometimes, watching a video isn’t enough. That’s where simulation-style training comes into play.

For example, researchers at New Jersey Institute of Technology, Robert Wood Johnson Medical School, and software company Robust AI have developed an AI-powered program to teach and simulate the basic tenets of laparoscopic surgery. Using the actual tools used in surgery, medical students complete exercises to transfer rings between pegs without dropping them and within short time constraints, mimicking the delicate movements surgeons need to complete with swift precision.

The team used convolutional neural networks to train the model to recognize the different components. Another neural network, trained on the correct sequence of actions a user should follow, then detects when a user is out of sequence, enabling the program to give feedback to correct their action.

A recent study from this year showed the program is as good and even slightly better than faculty human evaluators when rating surgical skills. Currently, students are using the program informally, but it is headed to become an official part of the curriculum. Since surgical training involves significant oversight and input from senior surgeons who are typically already inundated with responsibilities, and since mistakes come with significant costs, improvements that allow students to do more realistic training in lower-pressure settings have enormous potential.

“An app like ours helps to reduce medical errors. Students can practice as much as they like in the app before they enter the operating room,” says Usman Roshan, an associate professor of computer science at New Jersey Institute of Technology who’s been collaborating on the program.

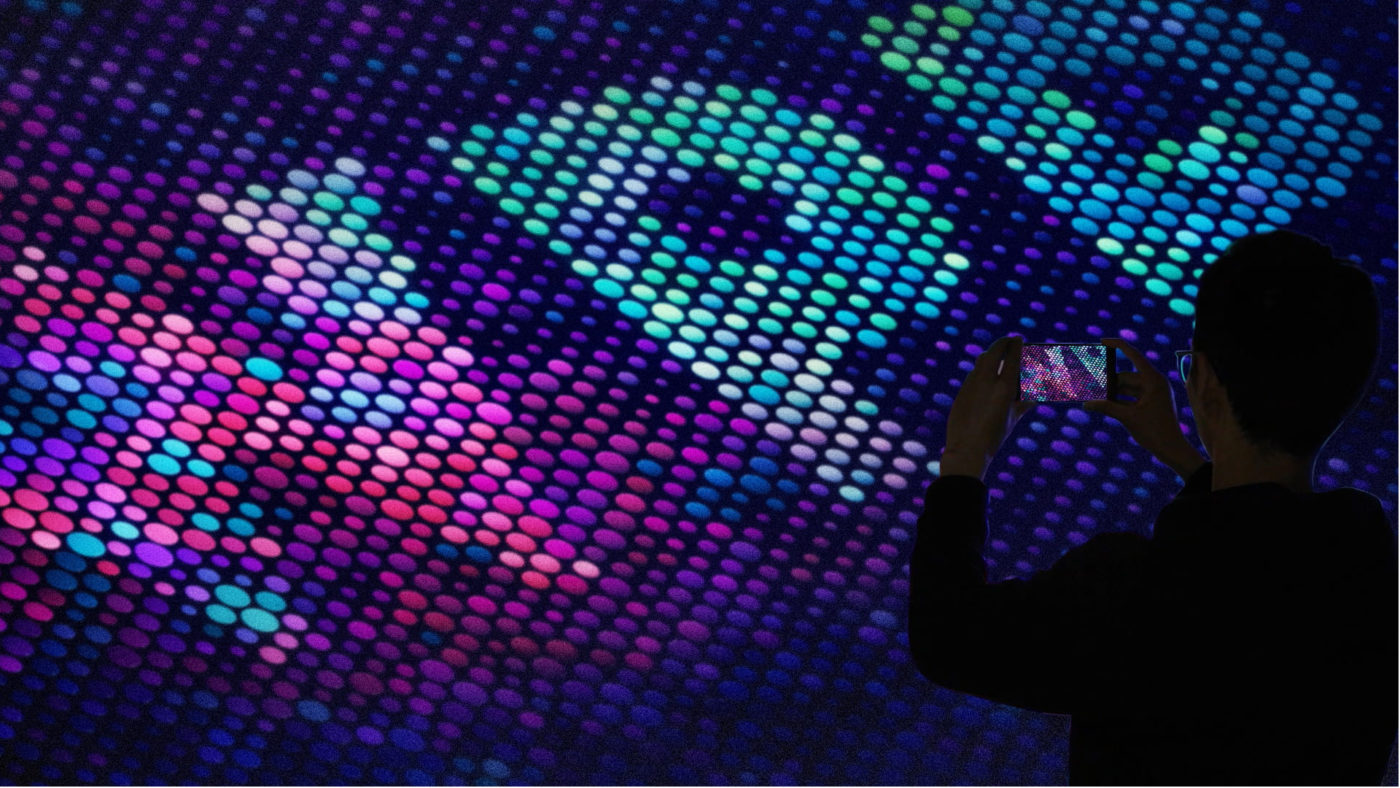

Benefits of improved AI-enabled simulation-style training stretch beyond the operating room, however. Strivr, a company combining AI and virtual reality to create immersive training experiences, is serving customers across logistics, transportation, retail, and other industries, such as Walmart, Verizon, and Amazon. Strivr uses AI to create custom content for customers (to build out avatars for 3D environments, for example) and also to power user-facing capabilities that make up the training experience, such as AI-powered dynamic conversation abilities. Previous trainings included only scripted dialogue, but recent advancements in AI are making it possible for users to engage in more naturalistic, nonlinear conversations with the avatars in their training simulations.

“AI allows for a more realistic, real-world applicable training experience,” says Strivr founder and CEO Derek Belch.

The pursuit of real-time training

Thanks to AI, Strivr is also making progress on its next frontier: augmented-reality-powered experiences that guide workers in real time and connect them to information they need while performing a job. The company is working with 10 design partners to build out early versions of its platform for real-time guidance, called WorkWise.

“The end result of all of this is going to be someone—let’s just say a warehouse worker—putting packages on a truck. They’re going to be wearing smart glasses, and the glasses are going to be telling them what to do in real time. This is kind of ironic, given what we’ve been doing for the last 10 years, but you’re probably not going to have to train people, or you’re going to significantly reduce the amount of training time required,” says Belch.

While smart glasses are still in their infancy and this vision is still a work in progress, AI is already powering real-time guidance experiences via smartphones and other wearable devices, and reducing the need for upfront training as a result. Alex Hawkinson, CEO of BrightAI, a company creating AI solutions for blue-collar industries, for example, worked with a manufacturer of custom pool covers to do just that. Traditionally, two workers would spend an entire afternoon manually measuring a pool and creating a CAD model to design the cover. The company developed an autonomous scanning system and accompanying copilot, or assistant tool, that gives real-time guidance to lead the process, build the models on the spot, and then creates the cost estimate for the job.

The real-time guidance dramatically speeds up the manufacturing process and reduces measuring errors, Hawkinson says, but it also makes these jobs more available to lesser trained workers. Across the various fields BrightAI works in, like HVAC and energy infrastructure, he says real-time guidance makes it possible to decrease the training requirements and productively deploy new hires.

“It doesn’t have to be a highly trained person to go out and measure. It talks directly to the manufacturing system,” he says. “So while the person is sitting there with the customer at their house, it shows the quote and what the cover is going to look like. It helps them visualize that with a copilot that we built for that worker, and then the customer can say ‘yes’ and it can be there in three days.”

This story was originally featured on Fortune.com