Scientists Create Artificial Leaf That Converts CO₂ into Fuel Using Photosynthesis Principles

Scientists have created an artificial leaf that turns CO₂ into fuel using sunlight and industrial waste. A real breakthrough in clean energy—read how it works.

Climate change, pollution, fossil fuel dependency—these are some of the most pressing issues of our time. But what if nature already held the blueprint for a cleaner, more sustainable future? In a groundbreaking advancement, scientists have developed an artificial leaf that mimics photosynthesis, turning sunlight and carbon dioxide into fuel. This innovation could fundamentally shift how we think about carbon emissions and energy production.

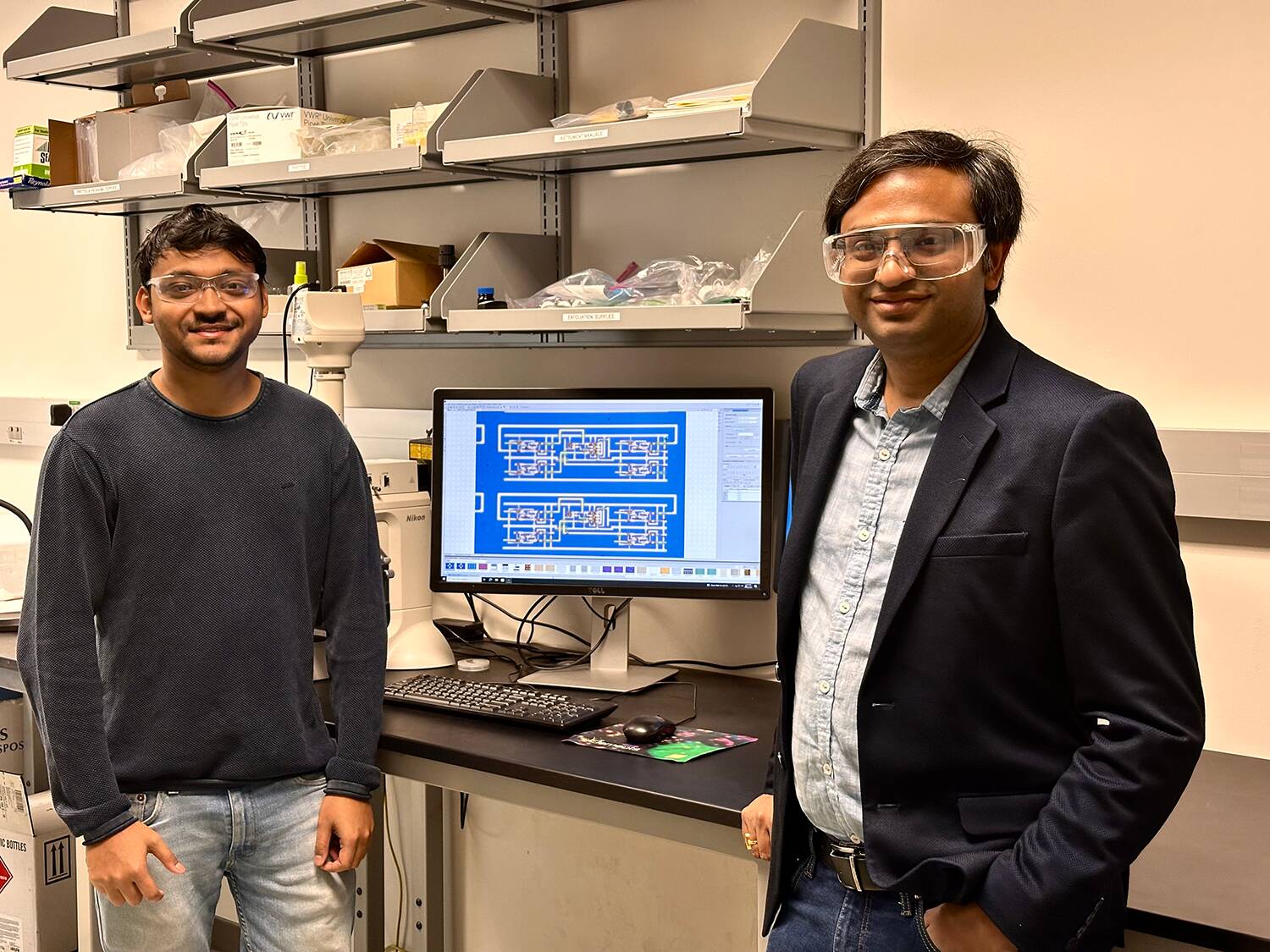

How The Artificial Leaf Works

At first glance, the term "artificial leaf" might conjure up images of plastic foliage, but the real deal is far more sophisticated—a compact, high-tech chemical system designed to replicate what plants do naturally.

The artificial leaf uses a sunlight-absorbing material called perovskite, a compound known for its excellent efficiency in harvesting solar energy. Perovskite acts like the chlorophyll in plants, capturing sunlight to drive chemical reactions. Paired with this is a catalytic surface covered in copper nanoflowers—microscopic structures that facilitate the conversion of CO₂ into useful carbon-based fuels.

These nanoflowers act like molecular midwives, helping to birth hydrocarbons such as ethane (a key component of natural gas) and ethylene (used in plastics, antifreeze, and a wide range of industrial products). The artificial leaf doesn’t just trap carbon—it transforms it into building blocks for modern life.

The Game-Changing Twist: Glycerol

Previous attempts at artificial photosynthesis struggled with a key challenge: splitting water to obtain hydrogen, a crucial ingredient for making hydrocarbons. The process demanded too much energy to be practical.

This new device, however, sidesteps that hurdle by using glycerol instead. A common byproduct in industries like biodiesel production, glycerol is typically discarded. But when used in the artificial leaf, it not only replaces water but dramatically boosts efficiency—by up to 200 times compared to earlier designs.

This clever substitution not only reduces energy requirements but also turns industrial waste into a valuable input. It’s a win-win: better efficiency and higher sustainability.

Beyond Fuel: More than just energy

Interestingly, the artificial leaf doesn't stop at hydrocarbons. It also produces glycerate, lactate, and formate—compounds with high value in pharmaceuticals and cosmetics. This means the technology has the potential to cleanly manufacture a wide variety of chemicals beyond just fuel.

The Roadblocks Ahead

While the concept is revolutionary, there are still challenges to overcome before we see artificial leaves at scale. The biggest issue is selectivity—currently, only about 10% of the CO₂ fed into the system gets converted into the desired hydrocarbons. The rest becomes byproducts.

Think of it like baking a cake and only 10% of your batter turning into actual cake. Researchers are now working on redesigning the copper nanoflowers to improve yield and efficiency.

Scaling the technology from lab-sized prototypes to industrial-scale systems will require significant investment, materials engineering, and testing. And like with most green tech, economic viability will play a crucial role in adoption.

A Glimpse into a Cleaner Future

Despite these hurdles, the artificial leaf represents a major step toward carbon-neutral fuel production. Imagine factories, power plants, or even aircraft hangars equipped with artificial leaves—capturing the CO₂ they emit and converting it back into usable fuel or chemicals, all powered by sunlight.

It’s not just science fiction anymore. With continued research and development, this innovation could help reshape our global energy systems—offering a circular, sustainable solution to some of the most daunting climate challenges.

Edited by Rahul Bansal