Watching This Humanoid Robot Sort Packages Is Quite Something

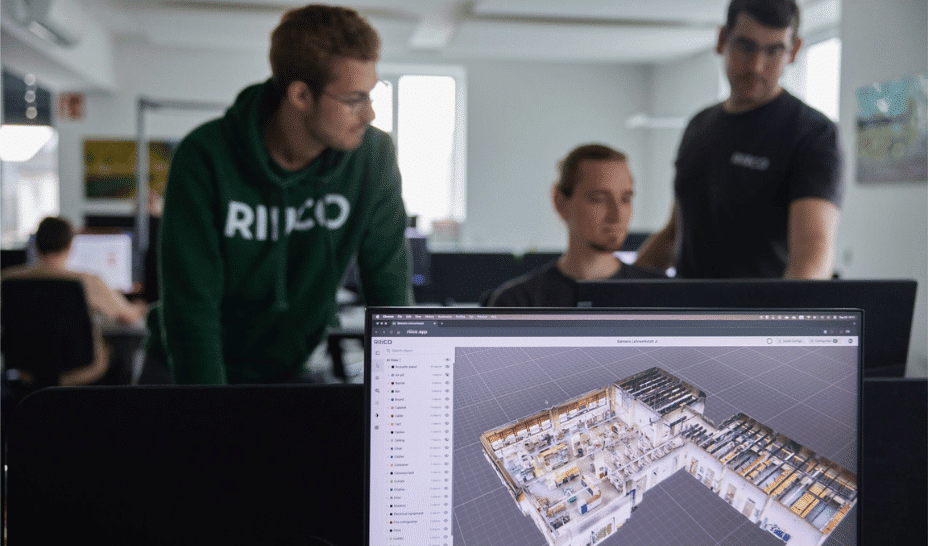

Post Flipper Earlier this year, humanoid robotics company Figure showed off its Figure 02 robot using a sophisticated visual language system called Helix to sort packages at a logistics warehouse. Footage showed the humanoid deftly picking up packages of various sizes, shapes, and hardnesses, and manipulating their orientation to have a barcode scanner identify them. Just three months later, the company has published an update about its Helix learning-based approach to robotics on its website, showing off its Figure 02 robot sorting an even wider variety of package styles, including deformed poly bags and flat envelopes. It's a remarkable feat […]

Package Deal

Earlier this year, humanoid robotics company Figure showed off its Figure 02 robot using a sophisticated visual language system called Helix to sort packages at a logistics warehouse.

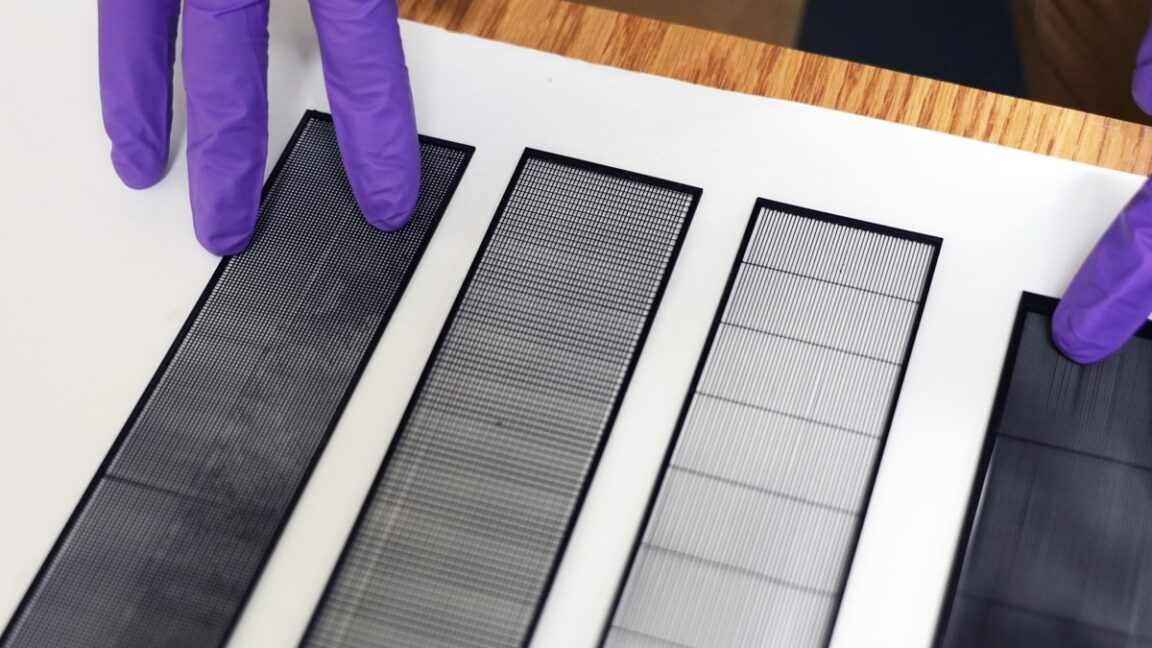

Footage showed a small army of the humanoid robots deftly picking up packages of various sizes, shapes, and hardnesses, and manipulating their orientation.

Just three months later, the company has published an update about its Helix learning-based approach to robotics on its website, showing off the same robot sorting an even wider variety of package styles, including deformed poly bags and flat envelopes.

It's a remarkable feat of robotics that highlights how close the tech is to completing human-level tasks in a warehouse environment, at least at specific tasks. Companies including Tesla and Agility Robotics are spearheading a concerted effort to automate repetitive human jobs — and judging by the latest results, we've never been closer to a future filled with bipedal robots crewing stations in commercial environments.

Watch Helix's neural network do 60 minutes of uninterrupted logistics work

Helix now incorporates touch and short-term memory and it's performance continuously improves over time pic.twitter.com/DvfBe9IdGH

— Figure (@Figure_robot) June 7, 2025

Pat Down

Figure claims its Helix system has steadily progressed in a matter of just months. Its robot is now spending just over four seconds per package, a second faster than before, while still maintaining accuracy. The company also says shipping labels are also correctly oriented for scanning 95 percent of the time, an improvement of 25 percent compared to earlier this year.

The robot can dynamically adjust to the unique shape of packages by "adjusting its grasp strategy on the fly — for example, flicking away a soft bag to flip it dynamically, or using pinch grips for flat mailers."

Figure 02 even pats down plastic packaging, a movement it's picked up through learning.

"This subtle 'flattening' action, learned from demonstrations, ensures the barcode is fully visible to the scanner," the company's update reads. "Such adaptive behavior highlights the advantage of end-to-end learning — the robot learns from demonstration strategies that were never explicitly hard-coded, directly from the data, to overcome real-world imperfections in packaging."

The race to fill warehouses with humanoid robots is on, and several companies are clamoring to become the de facto leader in the burgeoning industry. The basic idea is to have one model of robots fulfil a number of different tasks, as opposed to a range of highly specific, purpose-built robots.

However, making them cost-efficient and reliable enough to actually replace human labor on a significant scale will likely still pose a significant challenge.

More on humanoid robots: Former Tesla Robotics Boss Casually Torches Elon Musk's Vision for Saving the Company

The post Watching This Humanoid Robot Sort Packages Is Quite Something appeared first on Futurism.

![X Highlights Back-To-School Marketing Opportunities [Infographic]](https://imgproxy.divecdn.com/dM1TxaOzbLu_kb9YjLpd7P_E_B_FkFsuKp2uSGPS5i8/g:ce/rs:fit:770:435/Z3M6Ly9kaXZlc2l0ZS1zdG9yYWdlL2RpdmVpbWFnZS94X2JhY2tfdG9fc2Nob29sMi5wbmc=.webp)

.png)