This strange Swiss tower takes 3D printing to new heights

One of the world’s most distinctive new buildings is now poking out of the center of a small village in the Swiss Alps. The structure, a cylinder of bone-white columns topped by a dome, wasn’t built in the traditional sense. It was 3D-printed. It’s now the tallest 3D-printed tower in the world, and it could offer a technique for other 3D-printed buildings to rise even higher. Standing on the base of an existing building, the tower rises to a height of 98 feet, with four floors connected by a central staircase. The tower itself is all structure, with 32 tree-inspired concrete columns forming a cage-like shell that’s open to the air. Gradually widening as it rises, the tower’s top floor is a double-height space with a wide circular platform that can hold dozens of people. [Photo: Birdviewpicture/Nova Fundaziun Origen] The tower is envisioned as a performance space for Mulegns, a village of just 11 people in southeastern Switzerland. The roof of an adjacent building has also been used as the base for tiered grandstand seating that faces the tower. [Photo: Birdviewpicture/Nova Fundaziun Origen] Known as Tor Alva, or White Tower in the local Romansh language, the project is a collaboration between the Swiss cultural foundation Nova Fundaziun Origen and the university ETH Zürich. It was designed by architect Michael Hansmeyer together with Benjamin Dillenburger, a professor of digital building technologies at the university. Possibly more consequential than its height, the tower’s columns are also load-bearing, which enables the structure to rise so high. A special concrete mixture had to be developed to make the project possible, and represents a novel solution to the problem of reinforcing 3D-printed concrete, which can be difficult to do without sacrificing the speed and cost-efficiency of additive manufacturing. Most other 3D-printed concrete buildings are single-story structures as a result. [Photo: Benjamin Hofer/Nova Fundaziun Origen] This new technique involves a combination of two robots: One robot acts as the 3D printer, applying concrete in layers, while the other places a ring-shaped reinforcement in the new structure every 20 centimeters. Additional rebar is added after printing. In total, it took five months to print the 32 main columns of the tower, each of which has a unique spiraling ornamentation. In total, the tower is made of 124 3D-printed pieces and has a vague resemblance to a layered cake. [Photo: Birdviewpicture/Nova Fundaziun Origen] This cake-like appearance is a reference to the region’s history of confectioners, who developed new cake and candy-making approaches and brought them to other parts of Europe. The village Mulegns was once a center of confectionary arts, but is now depopulating. Tor Alva is seen as a new tourist attraction. Tor Alva is planned to sit in the village for around five years, after which it can be dismantled and reconstructed elsewhere. So, not only is it the tallest 3D-printed building, it could also be the first 3D-printed tower to pick up and move.

One of the world’s most distinctive new buildings is now poking out of the center of a small village in the Swiss Alps. The structure, a cylinder of bone-white columns topped by a dome, wasn’t built in the traditional sense. It was 3D-printed. It’s now the tallest 3D-printed tower in the world, and it could offer a technique for other 3D-printed buildings to rise even higher.

Standing on the base of an existing building, the tower rises to a height of 98 feet, with four floors connected by a central staircase. The tower itself is all structure, with 32 tree-inspired concrete columns forming a cage-like shell that’s open to the air. Gradually widening as it rises, the tower’s top floor is a double-height space with a wide circular platform that can hold dozens of people.

The tower is envisioned as a performance space for Mulegns, a village of just 11 people in southeastern Switzerland. The roof of an adjacent building has also been used as the base for tiered grandstand seating that faces the tower.

Known as Tor Alva, or White Tower in the local Romansh language, the project is a collaboration between the Swiss cultural foundation Nova Fundaziun Origen and the university ETH Zürich. It was designed by architect Michael Hansmeyer together with Benjamin Dillenburger, a professor of digital building technologies at the university.

Possibly more consequential than its height, the tower’s columns are also load-bearing, which enables the structure to rise so high. A special concrete mixture had to be developed to make the project possible, and represents a novel solution to the problem of reinforcing 3D-printed concrete, which can be difficult to do without sacrificing the speed and cost-efficiency of additive manufacturing. Most other 3D-printed concrete buildings are single-story structures as a result.

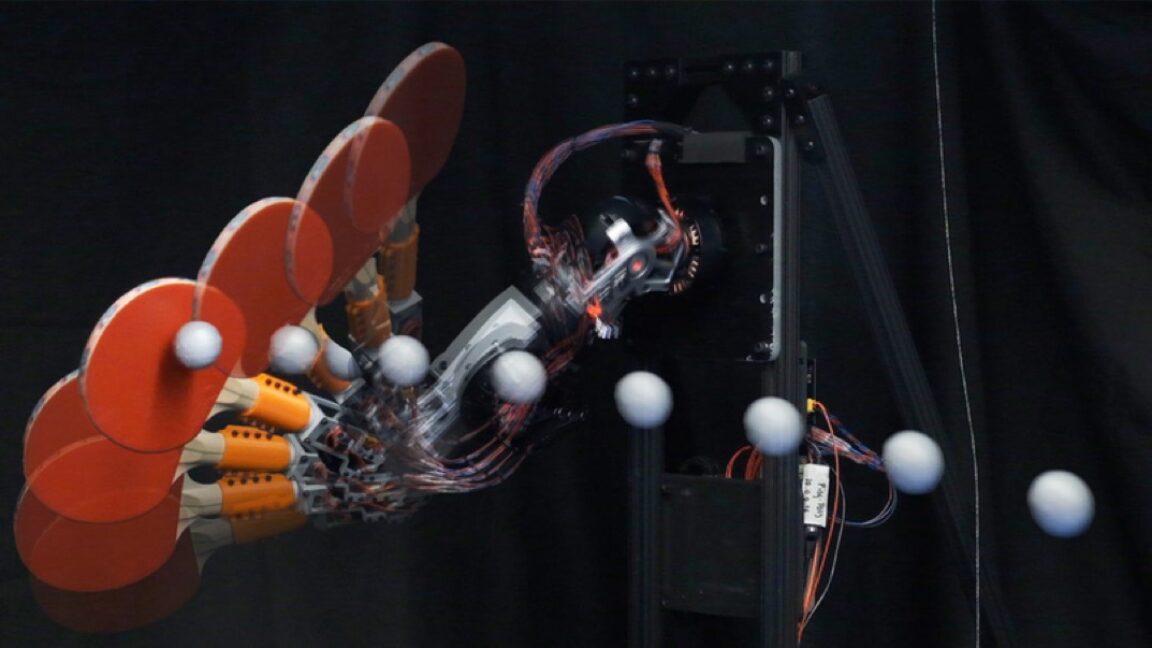

This new technique involves a combination of two robots: One robot acts as the 3D printer, applying concrete in layers, while the other places a ring-shaped reinforcement in the new structure every 20 centimeters. Additional rebar is added after printing. In total, it took five months to print the 32 main columns of the tower, each of which has a unique spiraling ornamentation. In total, the tower is made of 124 3D-printed pieces and has a vague resemblance to a layered cake.

This cake-like appearance is a reference to the region’s history of confectioners, who developed new cake and candy-making approaches and brought them to other parts of Europe. The village Mulegns was once a center of confectionary arts, but is now depopulating. Tor Alva is seen as a new tourist attraction.

Tor Alva is planned to sit in the village for around five years, after which it can be dismantled and reconstructed elsewhere. So, not only is it the tallest 3D-printed building, it could also be the first 3D-printed tower to pick up and move.

![[Weekly funding roundup May 24-30] Capital inflow continues to remain steady](https://images.yourstory.com/cs/2/220356402d6d11e9aa979329348d4c3e/Weekly-funding-1741961216560.jpg)