Cleaning solar panels with no water: Photom Technology’s robots are making it happen

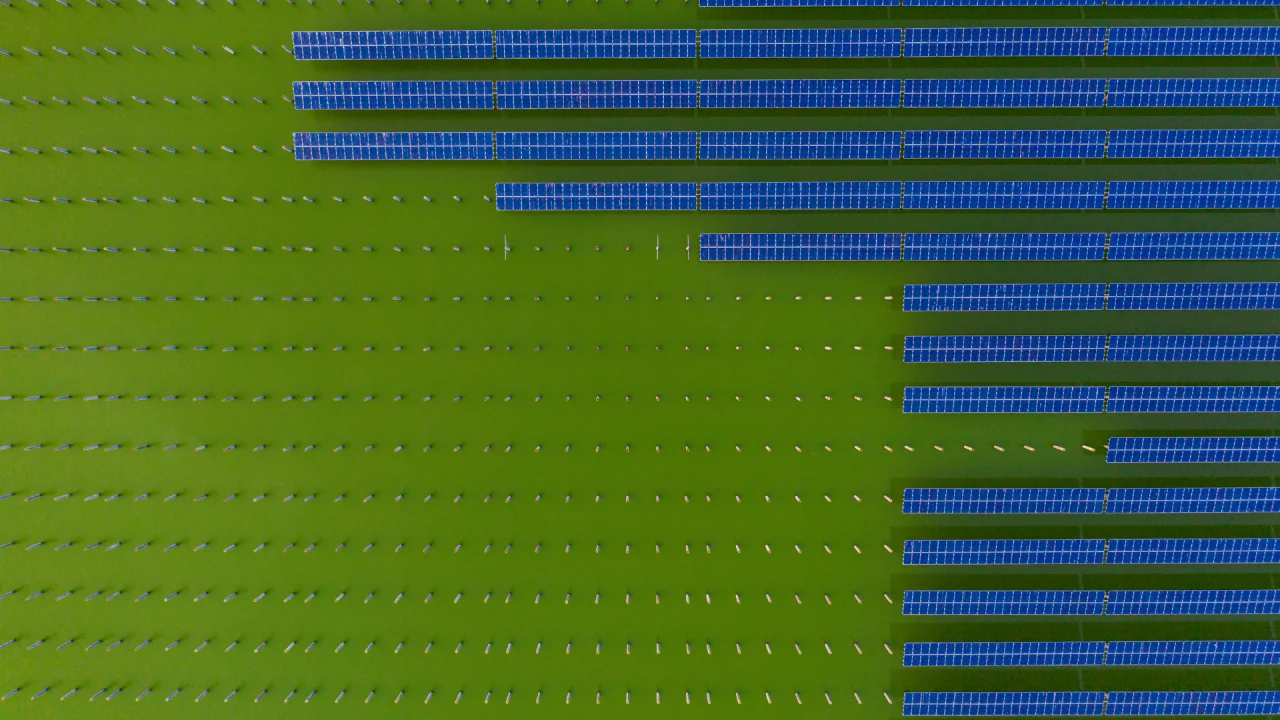

As India expands its solar footprint, maintenance remains a critical challenge. Photom Technology is betting on robotics and automation to make solar cleaning smarter and waterless.

Indians are rapidly adopting solar energy, thanks to various schemes launched by the Indian government, including the PM Surya Ghar: Muft Bijli Yojana, the Grid-Connected Rooftop Solar Programme, and the PM-KUSUM scheme.

According to the Ministry of New and Renewable Energy (MNRE), India’s solar power capacity stood at 110.83 GW as of May 31, 2025.

Considering the large-scale installation of solar panels in the country, cleaning these panels for their efficient functioning and to avoid dust accumulation is imperative. Ahmedabad-based startup Photom Technology is addressing this with a waterless robotic cleaning solution designed to keep panels dust-free and functioning optimally.

In 2018, Himmat Singh, Founder and CEO of Photom Tech, first realised how much dust build-up cuts solar panel efficiency during his environmental engineering project while pursuing civil engineering at IIT Research and Management in Ahmedabad.

“Dust can reduce energy output by up to 30% if panels go uncleaned for a month. But the alternative, regular water-based cleaning, brings its own set of challenges, especially in arid regions like Rajasthan and Tamil Nadu,” the 30-year-old founder says.

Singh, who hails from Rajasthan’s Pali district, started building his prototype in 2017. He launched Photom Technology the next year. While the company is registered in Pali, its manufacturing and operations are based in Ahmedabad.

Dry cleaning for solar panels

Photom’s main product is a battery-powered robot designed to clean solar panels without water. It uses rotating brushes, airflow, and contact pressure to dislodge and remove dust.

Singh says the robot is customised “based on geography; dust in Tamil Nadu is different from that in Rajasthan”. However, these robots are also capable of working autonomously through a web dashboard, where users can schedule cleaning and monitor performance.

“It’s a dry-cleaning system in the literal sense. No chemicals, no water. Just calibrated mechanical force,” he explains.

Each robot is priced between Rs 1.3 lakh and Rs 1.6 lakh, depending on configuration. “In one day, we clean 1.5 megawatts, though robots can clean 5000 panels per day,” the founder says.

Photom also offers annual maintenance contracts at roughly 15% of the robot’s base cost. “Clients receive a full-stack service, from manufacturing to post-installation support.”

The startup began commercial sales in 2021, following early pilots with Tata Power. Since then, the company has sold nearly 400 units and is working with seven utility-scale clients, including Torrent Power, Sprng Energy, and Juniper Green Energy.

Foraying into B2C and exports

Photom Technology has also built a smaller version of its robot, priced at Rs 30,000, and aimed at households and housing societies with rooftop solar panels. The product—first unveiled at the Renewable Energy India Exhibition in October 2024—hasn’t been commercialised yet.

“It’s undergoing certification and additional safety testing. We plan to commercialise it by the end of this financial year,” Singh says.

Recently, Photom made its first international sale, sending three robots to Sri Lanka’s WindForce, a utility-scale renewable energy producer operating solar, hydro, and wind power plants. “If the pilot goes well, the deal could grow to 100 units,” Singh says. It is also exploring the Middle East markets for future expansion.

Besides, Photom is also developing an automated maintenance software system (AMS) to collect operational data from solar plants and provide predictive maintenance insights. “The system is piloted across 26 installations and is scheduled for full release in January 2026,” Singh says.

According to him, this new system is about long-term viability. “The operations and maintenance (O&M) phase of a solar plant lasts for 25 years. If we can help predict component failures or optimise cleaning cycles, it has a direct financial impact on plant operators.”

The AMS is developed in-house, along with the rest of Photom’s stack, including its cloud dashboard. The company relies on platforms like Google Cloud and AWS for data handling, but has built its control systems, AI models, and interface layers internally.

In 2019, Photom raised a Rs 30 lakh incubation grant from iCreate and a Rs 70 lakh investment from ONGC in 2022. It reported Rs 1.3 crore in revenue for FY25 and Rs 1.4 crore in the previous fiscal year.

At present, it is in talks with two angel investors to raise funds within the next six months. “The round will help us develop our AMS platform further and scale up production,” Singh says.

With a team of 16 people, Photom Technology manages operations across six Indian states, of which 12 manage the tech operations. “We have trained solar plant technicians to do basic servicing. Our system gives remote diagnostics, and critical spares are stocked at the site. That helps us stay lean,” Singh explains.

The startup’s pipeline also includes expanding its O&M services. It began offering comprehensive solar plant maintenance earlier this year and aims to manage 2 gigawatts of solar capacity by the end of 2026. It is working with smaller industrial clients in Gujarat and Rajasthan to deliver these services. The pricing model for O&M services differs from that of robots, approximately Rs 3 lakh per megawatt annually.

Globally, players like Israel’s Ecoppia dominate the space. In India, Delhi-based SolarBot Technologies is a serious competitor for Photom Technology. Singh says the challenge is less about building a product and more about ensuring it works reliably over a two-decade period.

The founder says securing funding has been the company’s biggest challenge. “Being a solo founder meant I had to learn everything the hard way. The 2022 round gave us confidence in the product, but it wasn’t enough to build a globally competitive company.”

Photom is targeting sales of around 1,000 robots by the end of this year. “We were focused on making sure our product was reliable and effective. Now, we’re confident in its performance and follow-up support,” Singh says.

Edited by Suman Singh