Wells Fargo warns Trump’s tariffs won’t bring back American manufacturing jobs, which will need a minimum $2.9 trillion investment to regain peak

“Returning U.S. manufacturing employment to a level that remotely resembles its historical peak will be an uphill battle,” the bank said this week.

- Despite President Donald Trump continuing to tout tariffs as a way to increase U.S. manufacturing, a Wells Fargo report from this week argues meaningfully increasing manufacturing employment will be an “uphill battle.” Tariffs have pushed companies to absorb costs or pass them down to consumers, which is not conducive to ramping up domestic workforce expansion.

As President Donald Trump continues to push tariffs as a strategy to bolster U.S. manufacturing, economists aren’t convinced his steep levies will have their intended economic effect.

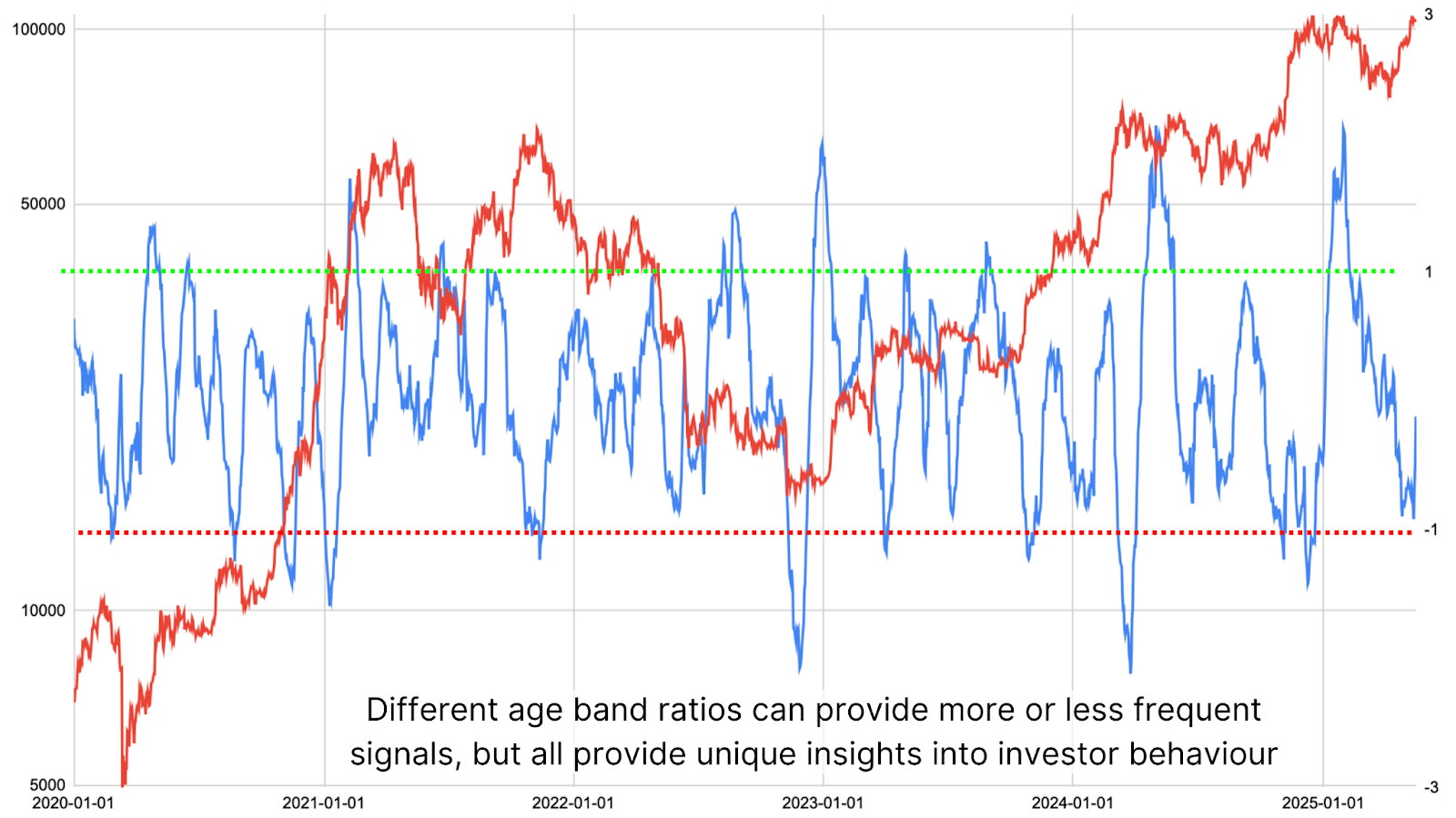

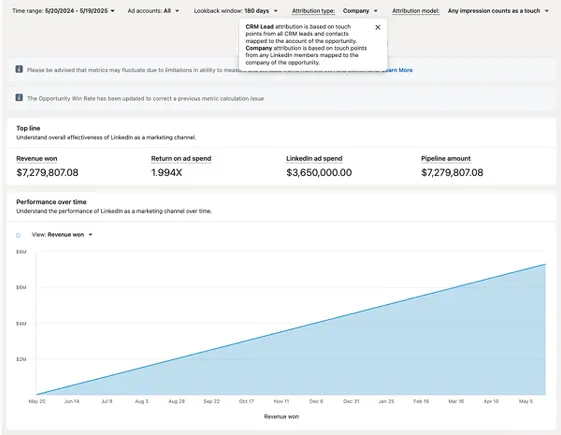

Manufacturing employment in the U.S. hovers at 12.8 million today, down from the country’s 1979 peak of 20 million, Wells Fargo said in a report on Wednesday. While the tariffs are intended to return American manufacturing to its heyday 45 years ago, they are instead creating a short-term environment that makes it harder for companies to expand their payroll and production efforts, according to the report.

“An aim of tariffs is to spur a durable rebound in U.S. manufacturing employment,” report author Sarah House wrote. “However, a meaningful increase in factory jobs does not appear likely in the foreseeable future, in our view.”

Despite putting a 90-day pause on some Chinese tariffs earlier this month and on “reciprocal tariffs” last month, Trump threatened on Friday a 50% tax on European Union imports beginning next month, as well as a 25% tax on Apple products unless the tech company starts making iPhones on American soil. Earlier this month, Trump said he had a “little problem” with Apple CEO Tim Cook, and asked him to stop producing the tech in India. Analysts have warned moving iPhone production to the U.S. would be a “non-starter,” adding thousands of dollars to the price tag.

Markets are reeling from Trump’s vow to implement more tariffs. Companies, including giants like Amazon and Walmart, have already warned tariffs will force them to either absorb costs through lower profit margins or pass down higher prices to customers. The taxes therefore are not conducive in the short term to growing one’s workforce, according to Wells Fargo.

In the medium to long term, the growth of U.S. manufacturing would take several years and require trillions of dollars in steady investment, the report said. Labor costs in the U.S. are sky high compared to the rest of the world, and executives like Pandora CEO Alexander Lacik have remained stubborn in refusing to move production to the U.S., insisting there’s a dearth of affordable and skilled American labor.

“I employ up to 15,000 craftspeople in Thailand,” Lacik said in a CNBC interview this month. “I can’t find that amount of talent that actually has this craft experience in the U.S.”

What would a manufacturing rebound take?

In theory, tariffs should help bolster domestic manufacturing by encouraging consumers to buy cheaper domestic goods, which in turn gives American producers reason to expand manufacturing and grow their workforce. Therefore, tariffs would need to be in place for several years at consistent levels in order to have their intended effects, Wells Fargo posited.

Should companies be able to navigate the short-term growing pains of the tariffs, they would also need to collectively invest massive new capital into expanding production, the bank said. Wells Fargo predicted a minimum of $2.9 trillion to be invested to expand U.S. manufacturing employment in order to return jobs to their 1979 peak.

Some major U.S. companies, including Apple, have already made commitments to expand production on home turf. Apple announced in February plans to invest $500 billion over the next four years in U.S. manufacturing, including plans for a new Texas factory. Johnson & Johnson, Merck, and IBM are others who have likewise invested in American production expansion.

The White House announced earlier this month that following Trump’s Middle East trip, Saudi Arabia will invest $600 billion in U.S. manufacturing, including a multibillion-dollar deal between Saudi aircraft renter AviLease and Boeing for 30 737-8 passenger aircraft.

While building out manufacturing infrastructure is one thing, attracting a workforce is another obstacle in growing domestic production. The National Association of Manufacturers predicts 3.8 million new manufacturing jobs by 2033, with about half of those positions going unfilled, the trade group said in a February report. Wells Fargo attributed these projected vacancies to an aging work demographic and tight immigration policies limiting population growth.

While the bank’s report suggested manufacturing jobs will need to be filled by a younger generation of working Americans, Gen Z doesn’t appear to be buying in. Just 14% of the generation said they would consider a career in factory work, according to a report from Soter Analytics. Many cited the jobs’ low wages, a result of a decline in unions in the manufacturing industry, labor experts say.

“Returning U.S. manufacturing employment to a level that remotely resembles its historical peak will be an uphill battle,” Wells Fargo said.

This story was originally featured on Fortune.com

.png)

![[Weekly funding roundup May 17-23] VC inflow remains steady](https://images.yourstory.com/cs/2/220356402d6d11e9aa979329348d4c3e/Weekly-funding-1741961216560.jpg)